3D Printing at Widener Impacts Lives and Inspires Careers

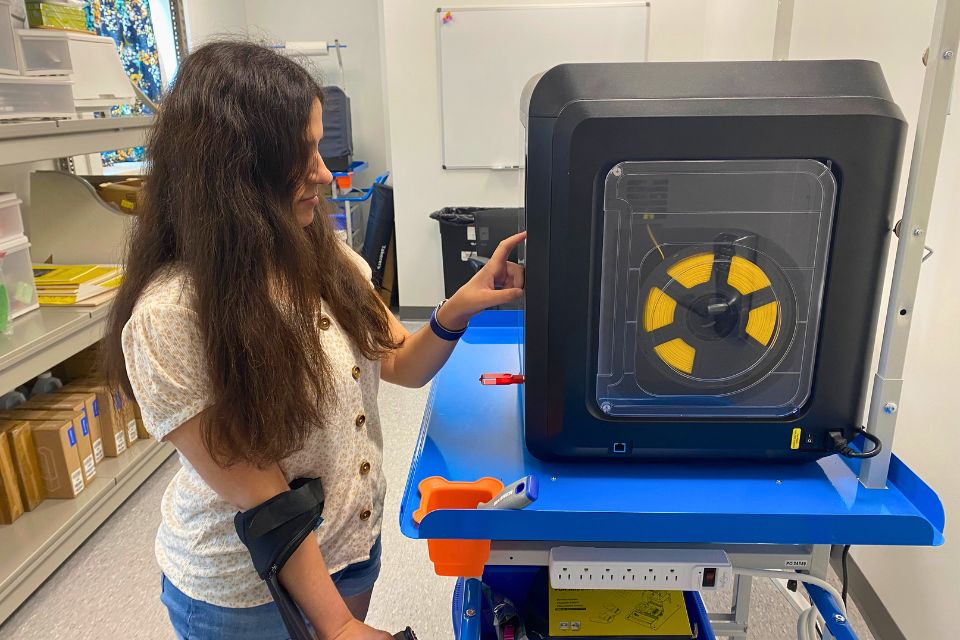

During a recent visit to the Maker’s Lab, the state-of-the-art technology sat dormant; a welcomed reprieve from the flurry of activity that filled the space throughout the fall and spring semesters by students from across campus.

Among the students busy in the Academic Center North space this past year was Lydia Aruffo ’25.

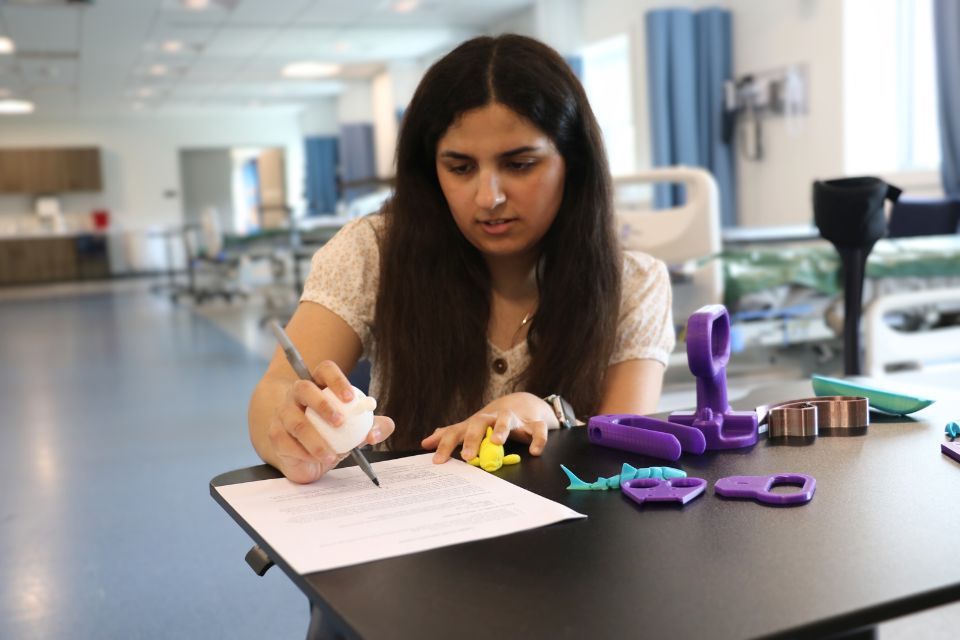

The occupational therapy student was a fixture in the lab as she designed and executed a customized 3D printed assistive technology capstone program for individuals with limited physical ability.

“My program applies the use of new 3D printing technology to alleviate the demands of specific tasks involved in desired occupations while also upholding inclusive design principles,” said Aruffo, who earned her doctoral degree in May.

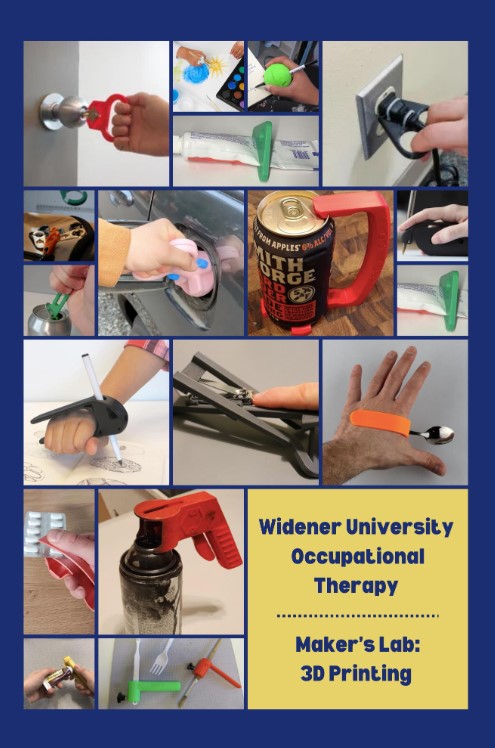

Aruffo created a catalog of assistive devices for individuals with Charcot-Marie-Tooth disease to help with a range of daily tasks from holding a soda can and opening a car’s gas tank cap to using nail clippers. The catalog featured nearly 25 items that Aruffo researched, acquired, and printed using open source coding files available online.

“The hand writing and key turning devices were the most popular by far,” Aruffo noted.

Charcot-Marie-Tooth disease, or CMT, is a group of genetic conditions that damages the peripheral nerves that send signals from the brain and spinal cord to the arms, legs, and limbs. Known as the most common rare disease in the world, CMT causes muscle weakness, loss of dexterity and coordination, and more, making everyday activities increasing difficult.

For Aruffo, who lives with CMT, the research was personal.

Her deep understanding and connection to the challenges her clients experience, along with her familiarity with using 3D printed devices, uniquely positioned her to build the program.

As a future occupational therapist, Aruffo was drawn to working with clients to help them achieve fulfilling lives safely and independently. Pursuing assistive technology in graduate school and now as a possible career, however, was not a pathway she anticipated.

Aruffo’s passion for 3D printing became apparent during a fieldwork placement at TechOWL, Pennsylvania’s Assistive Technology Act program that connects people with disabilities with the tools and technology they need to be independent.

“I have always been interested in environments and assistive technology,” said Aruffo, who added that, “it turned out to be perfect because when I was at TechOWL during my fieldwork I found out that I loved 3D printing.”

Using her newly acquired 3D printing skills, Aruffo partnered with individuals from the Charcot Marie Tooth Association seeking assistive technology. She worked one-on-one with approximately 10 clients to understand their needs and limitations and recommend a device from her carefully curated catalog.

When a specific item wasn’t listed in her collection, Aruffo dove into research to match the client with what they needed.

“Some participants kind of went off script and we found different things that would address their needs better,” Aruffo said.

Personalization is a core component in the Maker’s Lab, and within the greater makers community, as clients often can’t simply purchase a device online or in a store. For Aruffo, building an inclusive program was critically important. Once a device was selected, printed, and shipped, Aruffo worked closely with clients to make alterations to improve usability and comfort.

“Changing even the smallest thing, you don't think it's like a huge deal, but it makes the biggest difference,” said Aruffo.

This project is the latest example of client-focused solutions produced by students in the university’s Maker’s Lab.

Since its launch, the lab has made strides in its mission of making affordable assistive technology for individuals with disabilities to improve their quality of life. A robotic arm reacher, an adaptable utensil and chopstick holder, and a discrete feminine product applicator are just some of the many student-designed solutions.

The lab enables this fast-growing area of technology to compliment the curriculum and give students like Aruffo the opportunity to learn how to transform clients’ lives with innovative and cost-effective technology.

“That was super cool to see how big the impact can be on people's lives and I've seen that in my own program now, too, and it just feels great because 3D printing is such an easy thing to do,” said Aruffo.

As one of the newest members of Widener’s alumni network, Aruffo aims to build on the success of her capstone program and launch a career centered on innovative client care.

“It just feels good to be able to make something that's going to help people,” said Aruffo.

Read the Summer 2025 Widener Magazine